PDA SOFTWARE SUITE

DESCRIPTION

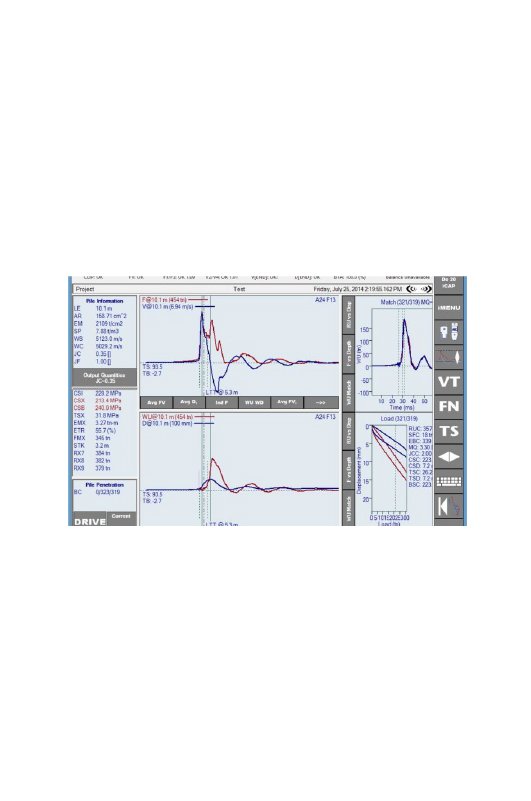

PDA-S with iCAP®

PDA-S offers a more intuitive interface than former PDA programs and allows users to check for program updates. With touchscreen as well as desktop functionality, it runs both in the PDA-8G and in an office computer during post-processing. This simplifies the software learning process. In addition to soil resistance at the time of the test, PDA-S calculates more than 230 other variables. PDA-S issues warnings and alerts during data input and acquisition. It outputs fully customized reports and graphs, reporting any number of variables and displaying up to three graphs in real-time.

iCAP calculates capacity at the time of testing and produces a simulated static load test graph through a fully automatic signal-matching procedure performed during Pile Driving Monitoring. The iCAP routine is easily accessed from the main PDA-S screen. Since iCAP is based on CAPWAP® signal matching logic, it is a step beyond capacity determined by the Case Method. (iCAP, provides a unique result and satisfies code requirements demanding a signal-matching analysis. However, the professional engineer, charged with providing due care, must evaluate the automatic solution by reanalysis with CAPWAP.)

PDIPLOT2

PDIPLOT2 generates tables and plots of any quantity calculated by PDA-S versus Blow Number, Length, Elevation, or any other quantity, and calculates their means and standard deviations. It provides the statistical summary output required by ASTM D4945 and is fully customizable.

PDI-Curves

Generates documents with up to six graphs per page, showing plots of Force-Velocity (required by ASTM D4945) or other quantities versus time, either from the same PDA-S file (for example five blows of a dynamic load test on a drilled shaft) or from multiple ones (one blow from each of five distinct piles on the same job site).

*SPT Analyzers include the PDA Software Suite without iCAP.

Visit the PDI Website for more information.